A water softener’s regeneration process directly impacts the size you need by determining how often and effectively the system can recharge itself to continue providing soft water. Choosing the correct size is crucial for ensuring the softener can handle your household’s specific water hardness and usage demands. At WaterSoftenerSizing.com, we understand that selecting the right water softener can be overwhelming. With various models, technologies, and sizing options available, it’s easy to feel lost in the sea of choices. That’s why we’re here to guide you through the intricacies of water softener sizing, starting with the often-overlooked factor of regeneration. The regeneration process, in essence, is the water softener’s way of cleaning itself. It involves flushing the system with a highly concentrated salt solution (brine) to remove the accumulated hardness minerals, primarily calcium and magnesium, from the resin bed. This resin bed is the heart of the water softener, where the ion exchange process takes place. The capacity of the resin bed, which is the amount of hardness minerals it can hold before requiring regeneration, is a critical factor in determining the overall size and efficiency of the water softener. An undersized water softener will regenerate too frequently, leading to excessive salt and water consumption, increased wear and tear on the system, and potentially inconsistent soft water delivery. Conversely, an oversized unit may not regenerate often enough, resulting in reduced efficiency and wasted capacity. In this comprehensive guide, we will delve into the different types of regeneration, their impact on sizing, and how to calculate the ideal size for your specific needs. We’ll also discuss advanced regeneration technologies, troubleshooting tips, and the role of reputable organizations like the Water Quality Association (WQA) in ensuring the performance and quality of water softeners. By the end of this article, you’ll be equipped with the knowledge to confidently choose a water softener that provides your home with a continuous supply of soft, luxurious water.

What is Water Softener Regeneration?

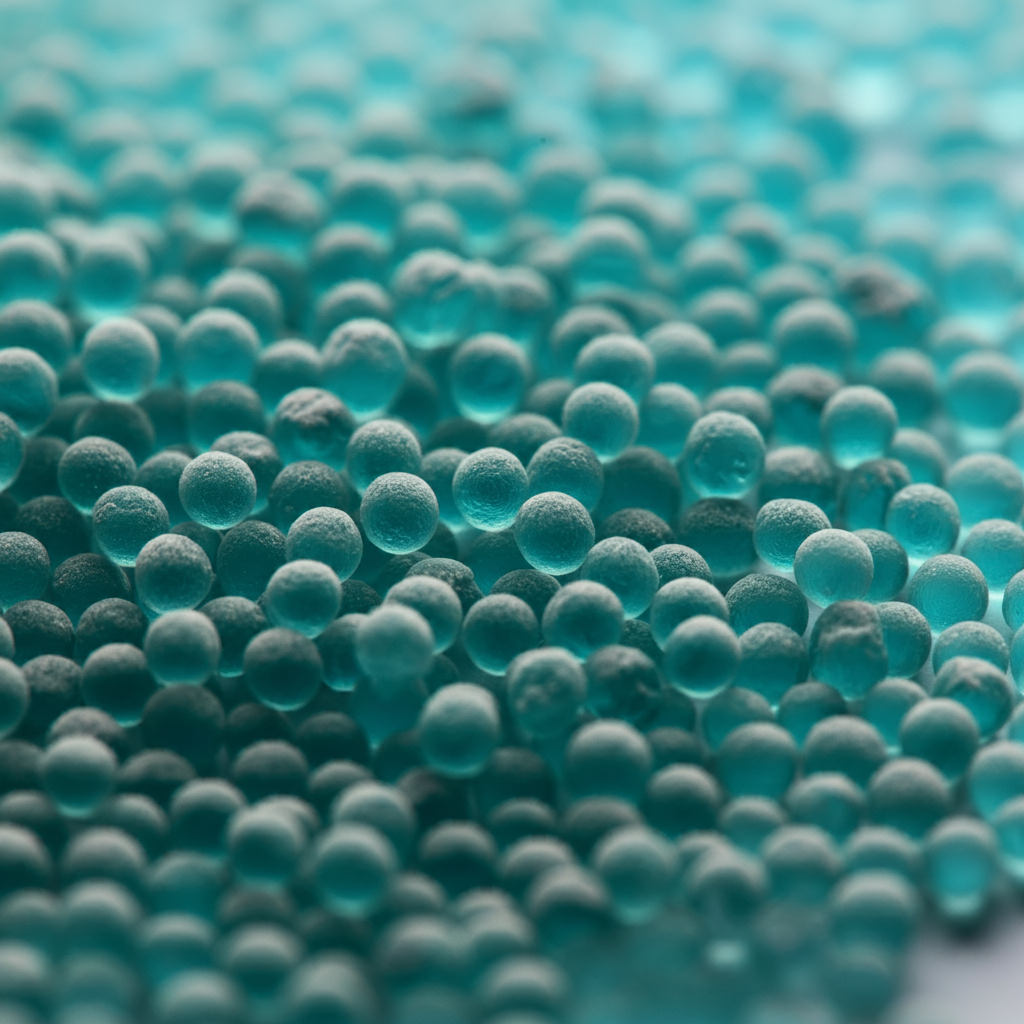

Water softener regeneration is the process by which a water softener cleans and recharges itself to continue removing hardness minerals from your water supply. Over time, the resin beads within the softener become saturated with calcium and magnesium ions, the culprits behind hard water. Regeneration essentially flushes these minerals out, restoring the softener’s effectiveness.

The Ion Exchange Process

Ion exchange is the core process that enables water softening. It involves the exchange of ions between two electrolytes or between an electrolyte solution and a complex. In the context of water softening, it specifically refers to the exchange of calcium (Ca2+) and magnesium (Mg2+) ions, which cause water hardness, with sodium (Na+) ions. The ion exchange process occurs within the resin bed of the water softener. This bed is filled with tiny resin beads, typically made of polystyrene, that are supercharged with sodium ions. As hard water passes through the resin bed, the calcium and magnesium ions are attracted to the beads and swap places with the sodium ions. This exchange effectively “softens” the water by removing the hardness minerals. Over time, the resin beads become saturated with calcium and magnesium, reducing their ability to soften water. This is where regeneration comes in. During regeneration, a highly concentrated brine solution (water saturated with sodium chloride, or salt) is flushed through the resin bed. The high concentration of sodium ions in the brine solution forces the calcium and magnesium ions off the resin beads and replaces them with sodium ions. This replenishes the resin bed and prepares it for another cycle of softening. Let’s break down the key entities involved in the ion exchange process:

- Resin bed: The container filled with resin beads where the ion exchange takes place. Think of it as a filter that traps hardness minerals.

- Resin beads: Tiny plastic beads coated with sodium ions. They act as magnets for calcium and magnesium ions.

- Calcium and magnesium ions: The minerals that cause water hardness. They are responsible for soap scum, scale buildup, and other hard water problems.

- Sodium ions: Harmless ions that replace calcium and magnesium during the ion exchange process.

- Brine solution: A highly concentrated salt solution used to recharge the resin beads during regeneration.

To visualize the ion exchange process, imagine a dance floor where calcium and magnesium are the unwanted guests. The resin beads are the bouncers who escort them out and invite sodium in as their replacements. The brine solution acts as a refreshment station for the bouncers, providing them with a fresh supply of sodium to keep the dance floor (your water) soft and enjoyable.

Types of Water Softener Regeneration

Water softeners utilize two primary types of regeneration: time-initiated regeneration (TIR) and demand-initiated regeneration (DIR). Each method offers distinct advantages and disadvantages, and understanding their differences is crucial for determining the optimal water softener size for your home.

Time-Initiated Regeneration (TIR)

Time-initiated regeneration operates on a preset schedule, typically every few days. Regardless of actual water usage, the softener will regenerate at the designated time. Pros:

- Simple and predictable: Easy to set up and maintain.

- Suitable for consistent water usage: Works well for households with relatively stable water consumption patterns.

Cons:

- Inefficient: May regenerate even when the resin bed isn’t fully exhausted, wasting water and salt.

- Risk of hard water breakthrough: If water usage spikes unexpectedly, the softener might run out of capacity before the next scheduled regeneration.

Demand-Initiated Regeneration (DIR)

Demand-initiated regeneration, on the other hand, is triggered by actual water usage. The softener monitors the volume of water passing through and initiates regeneration only when the resin bed’s capacity is nearing exhaustion. Pros:

- Efficient: Regenerates only when necessary, conserving water and salt.

- Adapts to fluctuating water usage: Ideal for households with varying water consumption patterns.

- Minimizes hard water breakthrough: Ensures a continuous supply of soft water even during peak usage periods.

Cons:

- More complex: Requires a meter to monitor water usage.

- May be more expensive: DIR systems often come with a higher upfront cost.

Comparing TIR and DIR

Think of TIR as a traditional alarm clock that goes off at the same time every day, regardless of whether you’ve had enough sleep. DIR, on the other hand, is like a smart alarm clock that wakes you up based on your sleep cycle, ensuring you’re well-rested. Similarly, TIR regenerates on a fixed schedule, while DIR adapts to your actual water usage, maximizing efficiency and minimizing waste.

How Does Regeneration Frequency Impact Water Softener Sizing?

The frequency with which your water softener regenerates is directly tied to its sizing. Essentially, the more often your softener needs to regenerate, the larger its capacity needs to be to avoid running out of soft water. To illustrate, imagine two households:

- Household A: A large family of six with multiple bathrooms and appliances that use a lot of water daily. Their water supply also has a high hardness level.

- Household B: A couple living in a smaller home with moderate water usage and moderately hard water.

Household A, due to higher water consumption and harder water, will deplete the softener’s resin bed faster, necessitating more frequent regeneration cycles. If their softener is undersized, they’ll experience periods of hard water between regenerations. Conversely, Household B, with lower water usage and less hard water, can go longer between regeneration cycles.

Capacity and Frequency: A Balancing Act

The capacity of a water softener is measured in grains, which indicates the amount of hardness minerals it can remove before needing regeneration. The higher the capacity, the longer the softener can go between regenerations. However, capacity alone doesn’t determine the ideal softener size. You also need to consider the frequency of regeneration, which depends on two main factors:

- Water hardness: Measured in grains per gallon (gpg), water hardness indicates the concentration of calcium and magnesium in your water. The higher the hardness level, the more frequently your softener will need to regenerate.

- Daily water usage: This is the amount of water your household uses on a daily basis. Higher water usage means more minerals passing through the softener, leading to faster resin bed exhaustion and more frequent regeneration.

To strike the right balance, you need a softener with a capacity that can handle your household’s daily water usage while accounting for the hardness of your water. If your softener is undersized, it will regenerate too often, wasting water and salt and potentially leading to periods of hard water. If it’s oversized, you’ll have excess capacity that goes unused, resulting in unnecessary expenses. Let’s break down this concept further with a real-world example. A family of four with a water hardness level of 15 gpg and daily water usage of 300 gallons would need a softener with a capacity of at least 4,500 grains (15 gpg x 300 gallons) to avoid frequent regeneration. However, if their water hardness level was 30 gpg, they would need a softener with double the capacity (9,000 grains) to maintain the same regeneration frequency.

Calculating Regeneration Frequency and Capacity

Understanding the relationship between regeneration frequency, water hardness, and daily usage is essential for accurate water softener sizing. While the precise calculations can be complex, we’ll provide you with a simplified approach and a valuable tool to make the process easier. Calculating Regeneration Frequency:

- Determine your water hardness: You can obtain this information from your local water supplier or by using a home water testing kit. Water hardness is typically measured in grains per gallon (gpg).

- Estimate your daily water usage: Calculate the average amount of water your household uses per day. You can find typical water usage figures for various appliances and activities online.

- Multiply water hardness by daily usage: This gives you the total grains of hardness your softener needs to remove daily.

- Factor in regeneration frequency: Most softeners are designed to regenerate about once a week. To calculate the required capacity, multiply your daily grain removal by 7 (days in a week).

Example: Let’s say your water hardness is 10 gpg and your household uses 300 gallons of water per day.

- Daily grain removal: 10 gpg * 300 gallons = 3,000 grains

- Weekly capacity: 3,000 grains/day * 7 days/week = 21,000 grains

This means you’ll need a water softener with a capacity of at least 21,000 grains to regenerate weekly and keep up with your household’s demand. Water Softener Sizing Calculator To simplify the process and ensure accurate results, we at WaterSoftenerSizing.com have developed a user-friendly water softener sizing calculator. Our calculator takes into account your water hardness, daily water usage, household size, and other relevant factors to recommend the optimal softener size for your specific needs. Important Considerations:

- Salt efficiency: Some water softeners are more salt-efficient than others, meaning they use less salt per regeneration. Consider this factor when choosing a softener, especially if you have concerns about salt usage.

- Future needs: If you anticipate changes in your household size or water usage, choose a softener with a slightly higher capacity to accommodate future needs.

- Professional consultation: For complex water conditions or if you’re unsure about the calculations, it’s always best to consult with a water treatment professional certified by the Water Quality Association (WQA). They can assess your specific needs and recommend the most suitable softener size and model.

Choosing the Right Size Water Softener

Choosing the right size water softener goes beyond just understanding regeneration frequency and capacity. Several other factors come into play, each contributing to the overall efficiency and effectiveness of your water softening system.

- Household Size: The number of people in your home directly impacts your daily water usage. A larger household typically consumes more water, requiring a softener with a higher capacity to accommodate the increased demand.

- Daily Water Usage: As discussed earlier, your daily water consumption is a key factor in determining regeneration frequency and the required softener size. It’s essential to consider the water usage of all appliances and activities, such as showers, baths, laundry, and dishwashing.

- Future Water Usage Projections: If you anticipate changes in your household size, such as a growing family or additional occupants, it’s wise to choose a water softener with a slightly larger capacity to accommodate future needs.

- Specific Water Needs: Do you have any specific water-related concerns beyond general hardness? For instance, if you have high levels of iron or manganese in your water, you might need a specialized softener with additional filtration capabilities. These factors can influence the type and size of softener you choose.

- Local Water Hardness: The hardness level of your water supply, measured in grains per gallon (gpg), is a crucial factor in determining regeneration frequency and softener capacity. You can obtain this information from your local water supplier or by conducting a water test.

To ensure you select the right water softener for your unique needs, we recommend consulting with a water treatment professional certified by the Water Quality Association (WQA). These experts have the knowledge and experience to assess your specific requirements and recommend the most suitable softener size and model. They can also help you interpret your water test results and understand the various features and technologies available in the market.

Water Softener Sizing Mistakes to Avoid

Choosing the right water softener size is a balance of art and science. While our calculator at WaterSoftenerSizing.com can guide you, it’s crucial to understand common sizing mistakes that can impact your water softener’s performance and lifespan.

Undersizing: A Recipe for Frustration

Imagine buying a car that’s too small for your family. It might work for short trips, but long journeys become uncomfortable and cramped. Similarly, an undersized water softener might handle your water needs occasionally, but it will struggle to keep up with regular demand. Consequences of undersizing:

- Frequent Regeneration: An undersized unit will exhaust its resin capacity quickly, leading to excessive regeneration cycles. This wastes water and salt, driving up your utility bills.

- Inconsistent Soft Water: If the softener regenerates too often, you might experience periods of hard water, especially during peak usage times. This can lead to soap scum, dry skin, and spotty dishes.

- Reduced Lifespan: The constant strain of frequent regeneration can shorten the lifespan of your water softener, leading to costly repairs or replacements sooner than expected.

Signs your water softener might be undersized:

- Hard water symptoms: If you notice soap scum, dry skin, or scale buildup on fixtures, your softener might not be keeping up with demand.

- Frequent salt refills: If you’re refilling the brine tank more often than expected, it could be a sign of excessive regeneration.

- Unusual noises or malfunctions: An overworked softener might make strange noises or experience mechanical problems due to the increased workload.

Oversizing: Not Always the Solution

While undersizing is a common issue, oversizing a water softener isn’t necessarily the answer. It’s like buying a huge SUV when you only need a compact car for daily commuting. Consequences of oversizing:

- Wasted Capacity: An oversized softener will have excess resin capacity that goes unused, leading to inefficient salt and water usage during regeneration.

- Higher Upfront Cost: Larger softeners generally cost more, so you’ll be paying extra for capacity you don’t need.

- Potential for Bacterial Growth: If the resin bed isn’t fully utilized between regenerations, it can become a breeding ground for bacteria, compromising water quality.

Optimizing Regeneration for Efficiency

While the regeneration process is essential for maintaining a water softener’s effectiveness, it’s equally important to ensure it operates efficiently. Several factors contribute to regeneration efficiency, ultimately affecting the longevity of your softener and its impact on your utility bills.

The Role of Salt in Regeneration

Salt plays a crucial role in the regeneration process. During regeneration, the brine solution, a highly concentrated salt solution, is used to flush the resin bed and replace the captured hardness minerals with sodium ions. The type and amount of salt you use can significantly impact the efficiency of this process. The most common type of salt used in water softeners is sodium chloride (NaCl), available in various forms such as rock salt, solar salt, evaporated salt, and potassium chloride (KCl). Each type has its own advantages and drawbacks, and the choice often depends on personal preference and budget. For instance, rock salt is the most affordable option but can leave sediment in the brine tank, potentially requiring more frequent cleaning. Solar salt and evaporated salt are purer forms of sodium chloride, dissolving more easily and minimizing sediment buildup. Potassium chloride is a good alternative for those concerned about sodium intake but can be more expensive.

The Importance of Regular Maintenance

Regular maintenance is vital to ensure optimal regeneration and prolong the lifespan of your water softener. This includes:

- Checking salt levels: Regularly check the salt level in the brine tank and refill it when needed. Low salt levels can lead to inefficient regeneration and hard water breakthrough.

- Cleaning the brine tank: Periodically clean the brine tank to remove salt residue and sediment buildup, which can hinder the regeneration process.

- Inspecting and cleaning the injector and drain line: These components are critical for proper brine flow during regeneration. Ensure they are clean and free of obstructions.

- Monitoring water softener settings: Check that the softener is programmed correctly for your water hardness and usage. Incorrect settings can lead to inefficient regeneration or wasted salt and water.

Advanced Regeneration Technologies

While time-initiated and demand-initiated regeneration are the most common methods, advancements in water softener technology have led to the development of more sophisticated regeneration techniques aimed at further optimizing efficiency and performance.

Proportional Brining

Proportional brining is a type of demand-initiated regeneration that takes efficiency a step further. Instead of using a fixed amount of salt for each regeneration cycle, proportional brining adjusts the amount of salt used based on the actual hardness minerals removed. This means that the softener only uses the necessary amount of salt for regeneration, minimizing waste and reducing operating costs. For example, if your water usage is lower than usual during a particular week, the softener will use less salt during the next regeneration cycle, adapting to your actual needs. This can result in significant salt savings over time, especially in households with fluctuating water usage patterns.

Electronic Control Valves

Electronic control valves have revolutionized water softener technology, offering precise control over the regeneration process. These valves use sophisticated algorithms to monitor water flow, hardness levels, and other parameters, ensuring that regeneration is initiated only when necessary and optimized for maximum efficiency. Compared to traditional mechanical timers or meters, electronic control valves offer greater accuracy and flexibility. They can be programmed with multiple regeneration cycles, customized settings for water hardness and usage, and even remote access for monitoring and adjustments.

Benefits of Advanced Regeneration Technologies

- Enhanced Efficiency: By tailoring regeneration to actual water usage and hardness levels, these technologies minimize water and salt waste, leading to lower operating costs and reduced environmental impact.

- Consistent Soft Water: Advanced regeneration ensures that your softener is always ready to provide soft water, even during peak usage periods, eliminating the risk of hard water breakthrough.

- Increased Lifespan: By optimizing salt usage and reducing the frequency of unnecessary regenerations, these technologies can extend the lifespan of your water softener, delaying the need for costly repairs or replacements.

- User-Friendly: Many advanced softeners come with intuitive interfaces and smartphone apps, making it easy to monitor and control your system remotely.

While advanced regeneration technologies often come with a higher upfront cost, their long-term benefits in terms of efficiency, performance, and convenience can make them a worthwhile investment. If you’re looking for a water softener that offers cutting-edge features and maximum efficiency, consider exploring models with proportional brining or electronic control valves. These technologies represent the future of water softening, providing homeowners with a reliable, cost-effective, and eco-friendly solution for combating hard water.

Making the Right Choice: Your Path to Perfectly Soft Water

The regeneration process of a water softener plays a pivotal role in determining the right size for your home. Understanding how regeneration frequency, capacity, water hardness, and daily usage intertwine is key to selecting a softener that delivers optimal performance, efficiency, and value. By carefully considering these factors, utilizing our sizing calculator, and seeking guidance from a Water Quality Association (WQA) certified professional, you can confidently choose a water softener that meets your specific needs and budget. Remember, a well-sized water softener not only eliminates the frustrations of hard water but also protects your plumbing, appliances, and fixtures, ensuring a long-lasting and enjoyable soft water experience.

Key Takeaways

- Regeneration is key: The frequency and efficiency of your water softener’s regeneration process directly impacts the size you need.

- Two types: Time-initiated regeneration (TIR) operates on a fixed schedule, while demand-initiated regeneration (DIR) adapts to your water usage, offering greater efficiency.

- Calculate carefully: Use our sizing calculator or consult a professional to determine the optimal softener capacity for your household’s water hardness and daily usage.

- Avoid mistakes: Undersizing leads to frequent regeneration and hard water issues, while oversizing results in wasted capacity and higher costs.

- Embrace technology: Consider advanced regeneration technologies like proportional brining and electronic control valves for enhanced efficiency and convenience.

- Maintain regularly: Proper maintenance, including salt checks and brine tank cleaning, ensures optimal regeneration and extends the lifespan of your softener.

At WaterSoftenerSizing.com, we’re committed to helping you navigate the world of water softeners and find the perfect fit for your home.

Ready to take the next step?

Use our free water softener sizing calculator to get a personalized recommendation, or contact our team of experts for personalized assistance. We’re here to ensure you enjoy the many benefits of soft water for years to come.

Craig “The Water Guy” Phillips is the founder of Quality Water Treatment (QWT) and creator of SoftPro Water Systems.

With over 30 years of experience, Craig has transformed the water treatment industry through his commitment to honest solutions, innovative technology, and customer education.

Known for rejecting high-pressure sales tactics in favor of a consultative approach, Craig leads a family-owned business that serves thousands of households nationwide.

Craig continues to drive innovation in water treatment while maintaining his mission of “transforming water for the betterment of humanity” through transparent pricing, comprehensive customer support, and genuine expertise.

When not developing new water treatment solutions, Craig creates educational content to help homeowners make informed decisions about their water quality.