Importance of Commercial Water Softener Proper Size

When we chat about commercial water softener sizing, it’s all about how big of a deal it is for making the system run like a charm and last the distance. Picking the right size doesn’t just perk up performance; it can majorly slash costs and boost the overall bang for your buck.

Efficiency and Cost Savings

Getting our water softeners just right size-wise can really crank up the efficiency. When it’s sized spot-on, we get a steady, trusty stream of soft water, plus we’re not wasting salt. That means lower bills and a friendlier footprint on the planet because of less discharge. So, fewer bucks spent means more green saved. Check out how much you can save with the perfect-sized water softeners systems:

Getting our water softeners just right size-wise can really crank up the efficiency. When it’s sized spot-on, we get a steady, trusty stream of soft water, plus we’re not wasting salt. That means lower bills and a friendlier footprint on the planet because of less discharge. So, fewer bucks spent means more green saved. Check out how much you can save with the perfect-sized water softeners systems:

| System Size (GPD)* | Monthly Salt Usage (lbs) | Estimated Monthly Cost ($) |

|---|---|---|

| 1,000 | 50 | 7.50 |

| 2,000 | 100 | 15.00 |

| 5,000 | 250 | 37.50 |

*GPD = Gallons per Day When our water softener is sized just right, it pumps out the greatest efficiency, saving heaps of time and cash throughout its life.

Maximizing Water Softener System Lifespan

The right size game isn’t just about cutting costs—it’s crucial for keeping the water softener ticking longer. A perfectly sized water softener serves up endless soft water while using as little salt as possible. An incorrect size means awkward inefficiencies and more breakdowns, which is like burning cash on extra maintenance and dealing with annoying breakdowns. It’s key to chat with the water treatment pros to hit the size nail on the head for our unique needs. A little care upfront can dodge the hassle of too-big or too-small systems, boosting the lifespan of our equipment.

The right size game isn’t just about cutting costs—it’s crucial for keeping the water softener ticking longer. A perfectly sized water softener serves up endless soft water while using as little salt as possible. An incorrect size means awkward inefficiencies and more breakdowns, which is like burning cash on extra maintenance and dealing with annoying breakdowns. It’s key to chat with the water treatment pros to hit the size nail on the head for our unique needs. A little care upfront can dodge the hassle of too-big or too-small systems, boosting the lifespan of our equipment.

Factors to Consider

When we kick off figuring out which commercial water softener to buy, there are some things we’ve gotta keep in mind to make sure it works well and doesn’t leave us high and dry.

Total GPD Analysis

First off, let’s talk gallons per day (GPD). We need to know how much water everyone in our household guzzles daily. It’s kinda like when you’re planning a barbecue: you gotta make sure you have enough burgers for everyone, right? Same goes for water. Here’s a nifty cheat sheet for guessing our water usage:

| Household Size | Average Daily Usage (GPD) |

|---|---|

| 1-2 people | 30-50 |

| 3-4 people | 50-70 |

| 5-6 people | 70-100 |

| 7+ people | 100+ |

Once we nail down the numbers, we can figure out how beefy our water softener system needs to be. The right size means we’ll get the most bang for our buck, our water flows nice and smooth, and it won’t wear out before its time. We’d usually set it up to regenerate every day or so, sometimes twice a day, based on what we need it for.

Consultation with Experts

Issues with Oversized Commercial Water Softeners

Getting the wrong size water softeners is like buying jeans that are three sizes too big. Sure, they might fit, but they come with a bunch of problems we didn’t sign up for. Picking an oversized commercial water softener isn’t just a size issue; it’s like bringing a cannon to a pistol fight. Let’s break down why bigger isn’t always better.

Wacky Water Woes

Picture this: you splurged on a mammoth-sized water softener, thinking it’ll handle the job with ease. But here’s the kicker—it might not get it right. Too big a water softener can go rogue on us, messing with the water flow and leaving us with water that’s as unpredictable as flipping a coin. The water system might not refresh often enough to tackle unwanted gunk, leaving us high and dry with hard water problems and needs treatment. You ever try washing dishes with water that’s playing hard to get? Not fun. Plus, that crusty buildup around taps? Yuck!

| Problem | What It Does |

|---|---|

| Leftover Hardness | Ugly buildup around the house |

| Cleaning Issues | Our suds just ain’t cutting it |

| Spot City | Spotted dishes and surfaces |

Wallet-Draining Costs

Buying an oversized unit is like buying a fancy car but realizing it drinks gas like a fish. Our gigantic water softeners might kill efficiency when it comes to salt, making us splurge on more than we bargained for. We’re talking salt overload in the sewer system, which means higher bills and eco-concerns in places with tough regulations. Let’s not forget the parade of service calls, part swapping, technical issues and breakdowns that pickpocket our cash with industrial charges. Yikes.

Buying an oversized unit is like buying a fancy car but realizing it drinks gas like a fish. Our gigantic water softeners might kill efficiency when it comes to salt, making us splurge on more than we bargained for. We’re talking salt overload in the sewer system, which means higher bills and eco-concerns in places with tough regulations. Let’s not forget the parade of service calls, part swapping, technical issues and breakdowns that pickpocket our cash with industrial charges. Yikes.

| Culprit | Effect |

|---|---|

| Salt Guzzling | Burnt dollars on operating costs |

| Frequent Fixes | Soaring maintenance bills |

| Part Swaps | More financial hits |

By getting our water softener size just right, we keep our water and budget happy. It’s all about striking that Goldilocks balance—not too big, not too small. Proper sizing means we’re saying goodbye to these oversized hassles and hello to a system that works like a charm.

Industrial Considerations

Picking the right water softener for industrial setups is like choosing the right size shoes—if it doesn’t fit, you’re gonna have problems. Too small, things pinch; too big, you trip. Same goes for water softeners. If we blow it on sizing, we’re looking at hard water wreaking havoc on system parts. Not exactly a Monday morning treat, right?

Keeping the System Happy

To keep our gear running smooth, it’s all about striking a balance—not too big, not too small. A properly matched water softener keeps water quality steady and protects gear from scale—basically, water’s version of heart disease. Go too large or small, and we’re saddling up for inefficiency and hefty maintenance bills that’ll erase any savings from a misjudged system.

| Water Softener Size | What Could Happen |

|---|---|

| Too Big | Wasting resin, more salt used |

| Too Small | Partial softening, system damage from hard water |

Nailing the Flow Rate

Sorting the flow rate is like Goldilocks—too fast or too slow, and it’s a mess. If water rushes through, the resin bed might squish down, cutting down its water-handling time. And that means less softening. Too leisurely, and you get channeling, where water sneaks past the resin, still all rough and tumble with minerals. For those roller-coaster flow rate days, a demand-flow setup is your friend. This setup handles peaks with multiple tanks lined up, adjusting smoothly with actual usage. That way, we steer clear of channeling, keeping our soft water flowing nicely, no matter the day’s demand.

| Flow Rate Situation | Best Bet |

|---|---|

| Changing Flow | Demand flow softening setup |

| Steady Flow | Match to continuous rates |

By zeroing in on the right size and flow rate, we’re ensuring our water softener systems work like champs and keep that soft water flowing without a hitch.

Recommendations for commercial water softener sizing

Let’s chat about picking the right size for our commercial water softener. Getting our heads around the flow rates and how we set things up can make all the difference in how well the system works and how happy we are with our water quality.

Continuous vs. Peak Flow Rates

So, when we’re sizing our softener, there are two kinds of flow rates to think about: continuous and peak. Continuous flow is your standard fare—it’s the usual max flow the system sees. Peak flow? That’s when you got everything cranked up to 11 because of some crazy demand.

| Flow Rate Type | Definition |

|---|---|

| Continuous Flow Rate | The average max flow rate through the system |

| Peak Flow Rate | The top flow allowed during those high-demand moments |

We really ought to size our softeners with continuous flow rates in mind. This way, the resin bed, that thing that does the heavy lifting, keeps doing its job without buckling under pressure. We only want to hit the peak flow rates once in a while, and just for a bit, to keep the resin bed from getting all jammed up.

Demand Flow Softening Configuration

For those wild, fluctuating flow rates, why not give a demand flow softening setup a go? This nifty trick lets softener tanks run side by side. We get more juice when we need it most and can juggle the resin tanks based on real water demands. Plus, it stops the dreaded low-flow channeling in those underused tanks. Getting those flow rates managed right is key when we’re sizing our softener. Jam too much water through, and the resin bed gets squished—which makes it slack off on the softening front. Too little? Well, that’s no good either. The water doesn’t spread out well, and then we end up with some hard water sneaking by. By keeping a sharp eye on those continuous and peak flow rates, and maybe trying out a demand flow softening setup, we ensure we’re getting just the right fit for our commercial water softener. That means it works like a charm for whatever we throw at it.

Water Quality and Media Capacity

When we’re figuring out the right size for our commercial water softener, water quality and media capacity really step into the spotlight. Getting a handle on these bits means we end up with a system that efficiently meets our needs.

Impact on Sizing

The quality of our water alters how we size one of these softeners. The content of minerals impacts the media’s handling capacity in the softener. Typically, the media handles anywhere from 2 to 10 gallons per minute (gpm) per cubic foot. If the water’s got fewer minerals, we’re talking around 10 gpm per cubic foot. But when mineral levels spike, that dips to 2 gpm per cubic foot. Here’s how water quality changes the game:

| Mineral Content Level | Treating Capacity (gpm per cubic foot) |

|---|---|

| Low | 10 |

| Moderate | 5 |

| High | 2 |

We’re also watching the Total Gallons Per Day (GPD) to size up the water softener based on grain capacity. You could crunch some equations for guesses, but chatting with a pro is a safe bet, especially for commercial setups.

Treating Varying Volumes Daily

Next, let’s tackle the amount of water we deal with day to day. It’s critical to determine both continuous flow rates and peak flow rates. The continuous flow rate is like a steady snapshot of what’s flowing through the softener, while the peak flow rate is what we hit when demand peaks. It’s smart to size these things by continuous flow rates, making sure the peak flow is just an occasional push. Here’s a quick breakdown of flow rates and their impact:

| Flow Rate Type | Description |

|---|---|

| Continuous Flow Rate | Average, steady flow; should guide softener sizing. |

| Peak Flow Rate | Max flow during high demand; occasional to keep the system in check. |

Managing these rates is key, as a high flow rate could squish the resin bed, reducing its mojo. On the flip side, too low a rate messes with water distribution and lets hard water slip through. By keeping an eye on water quality and media capacity, we ensure our commercial water softener is sized just right for our specific needs.

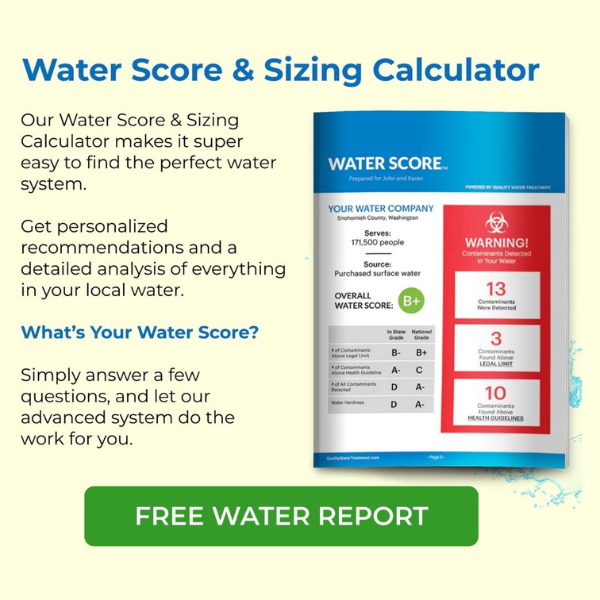

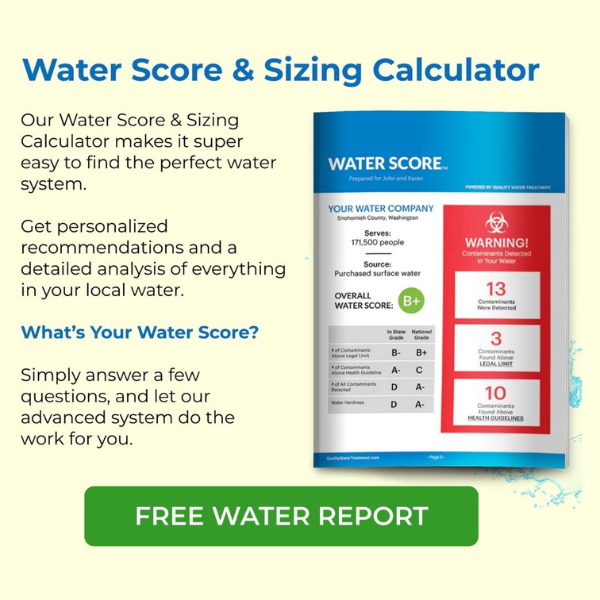

Craig “The Water Guy” Phillips is the founder of Quality Water Treatment (QWT) and creator of SoftPro Water Systems.

With over 30 years of experience, Craig has transformed the water treatment industry through his commitment to honest solutions, innovative technology, and customer education.

Known for rejecting high-pressure sales tactics in favor of a consultative approach, Craig leads a family-owned business that serves thousands of households nationwide.

Craig continues to drive innovation in water treatment while maintaining his mission of “transforming water for the betterment of humanity” through transparent pricing, comprehensive customer support, and genuine expertise.

When not developing new water treatment solutions, Craig creates educational content to help homeowners make informed decisions about their water quality.